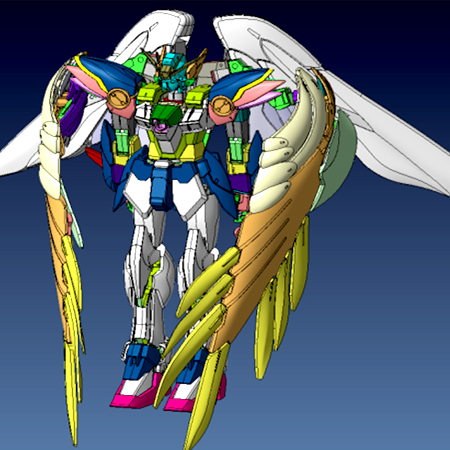

Internationally-acknowledged Company with Leading Technology Development

FINEDNC’s development ability has been recognized both in South Korea and overseas. We always continuously apply ourselves to every mission with the challenging spirit to go further and provide more advanced technology.